Stationary Engines

Stirling

cycle engine

The Stirling engine is a wonderful demonstration of the principles of thermodynamics, a subject close to my heart. Perhaps I was being whimsical, but I wanted to make a transparent displacer chamber from a wine bottle. It took a lot of practice (and many bottles) to cut a suitable glass cylinder. It is soothing and beautiful to watch, and it runs for nearly two hours resting on a hot (insulated) cup of coffee.

Here it is, silently spinning on my mantlepiece, day after day, month after month, year after year. It is powered from a 5 watt resistor and has been running continuously for 7 years so far…

See it running on YouTube…

This image was taken during building. The geometry did not allow for overhung cranks, and the double-ended crankshaft runs in 3mm ball bearings lubricated with long life clock oil.

Originally, I used a brass power piston and cylinder, but to keep the engine running continuously for years, I have replaced these with graphite, and eliminated the dust with a glass dome. Here's another view showing the small hot-plate (running from a mobile phone charger), the graphite power cylinder and the wine-bottle displacer cylinder. The displacer is made of polystyrene foam.

The design is often called "low temperature differential". This one runs with a temperature difference down to 12 C between the black top plate and the aluminium bottom plate.

“Model Dockyard”

Stationary Engine

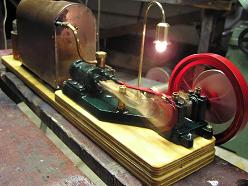

My father bought castings for this engine at a garage sale

when I was a small boy. Model Dockyard

was a hobby supplier in Swanson St, Melbourne, and through the Australian Model

Engineer magazine I was able to locate original blueprints. Recently (50 years later), I finished it for

Dad, then added a boiler and electric generator.

(Click images for a larger view)

This is the vapourising burner, of

my own design, burning methylated spirits.

And here are the components of the burner. The chicken-feeder design ensures that the

output stays constant as the metho is burnt.